Dallas, TX

Phone: (972) 423-0122

Address: 1100 Jupiter Rd Ste 121, Plano, Texas 75074

Services We Offer

- Gunite Pools

- Fiberglass Pools

- Pool Remodels

Dallas, TX Inground Pool Builders

Pinnacle Pools & Spas have the skill and experience to create a custom inground gunite & fiberglass swimming pool for any home or business in Dallas, Texas. Our years of expertise result in beautiful and long-lasting pools, from design to installation. We are dedicated to providing you with premier service and top-notch products – a combination that will give your backyard an incredible oasis tailored just for you! Our knowledgeable staff is always ready to help – no questions about maintenance or repair needs go unanswered, ensuring a smooth process every step of the way. Let us assist you in building your dream fiberglass pool today!

Top Pool Builders in Dallas

Eye-catching inground pools designed to suit your style are our specialty! Through custom gunite & fiberglass constructions, coupled with advice on budgeting and everything involved in the building phase, we make the dream of a perfect outdoor space come true. Our team of experienced specialists at Dallas’s #1 inground pool builder has earned an outstanding reputation in Dallas and beyond. Whether you’re a return customer or new to us – don’t hesitate to get in touch today – together let’s create something great that you’ll be proud of for years!

Call us at (469) 909-1638 or fill out the form below for a free quote.

Fiberglass Pool Installation

Learn more about fiberglass pools

Pinnacle Pools & Spas of Dallas, TX is a fiberglass pool builder offering quality services for residential and commercial clients. Our team of experienced professionals are dedicated to providing you with the highest quality craftsmanship and customer service possible. We specialize in building custom-designed pools with maximum efficiency, durability, and beauty. Our services include the full range of design and installation for your fiberglass pool project needs. From basic designs to complex pool features such as waterfalls or vanishing edges; we have the knowledge and experience to meet your every need.

Gunite Pool Builder

We are the premier provider of gunite pool construction services in Dallas. By combining our expertise in custom designs and installation with your vision, we can create a stunning backyard oasis that will bring years of enjoyment and relaxation to you and your family. Our team provides complete turnkey solutions for constructing new gunite pools. From choosing materials to dealing with local codes, we do it all – while making sure you’re kept informed every step along the way.

Pool Remodeling

Learn more about pool remodeling

We provide a wide range of pool remodeling services to suit any budget, including but not limited to pool resurfacing, tile/coping installation and repair, plumbing upgrades and maintenance as well as filter system replacements. With years in business, we have a vast knowledge base that allows us to make your dream outdoor space come true quickly and efficiently while maintaining the highest standards of quality workmanship. Whether you’re looking for large-scale projects like relining an entire pool or just minor touch-ups such as replacing old tiles – Pinnacle has you covered!

Call us at (469) 909-1638 or fill out the form below for a free quote.

Dallas, TX

Phone: (469) 909-1638

Address: 1100 Jupiter Rd Ste 121, Plano, Texas 75074

Dallas Inground Pool Builders

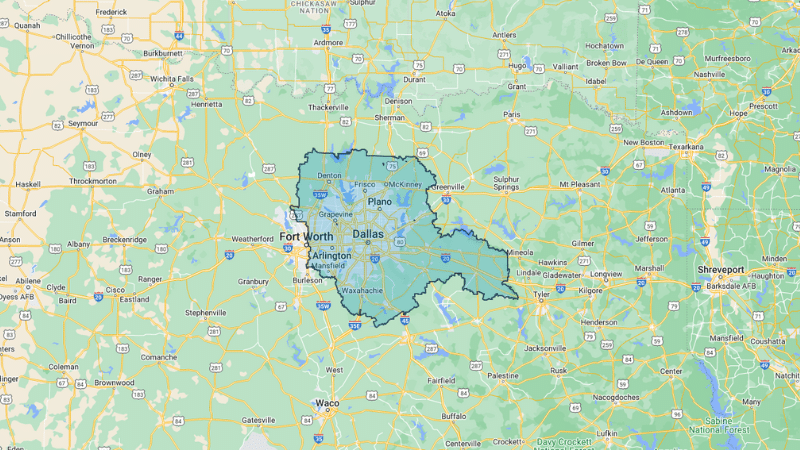

We build custom inground gunite & fiberglass pools in Dallas, Plano, Frisco, Arlington, Canton, Fort Worth, Irving, Garland, Rockwall, Flower Mound, Frisco, and everywhere in between.

Create beautiful, lasting memories in your backyard with the dependable and superior pool construction services our team offers Dallas homeowners. Let us help you turn your backyard into a joyous, relaxing environment with an exquisite inground swimming pool.

Where we build pools

Get a FREE Quote

Design A Pool

Design your future inground pool and receive a free quote from a professional Pinnacle Pools & Spas pool builder near you.

Finance your pool

Quickly apply for pool financing in just a few easy steps.